Frequently Asked Questions

-

Arbor is a new kind of energy company. We’re developing a novel system that both produces clean electricity and removes carbon dioxide—creating true carbon-negative power.

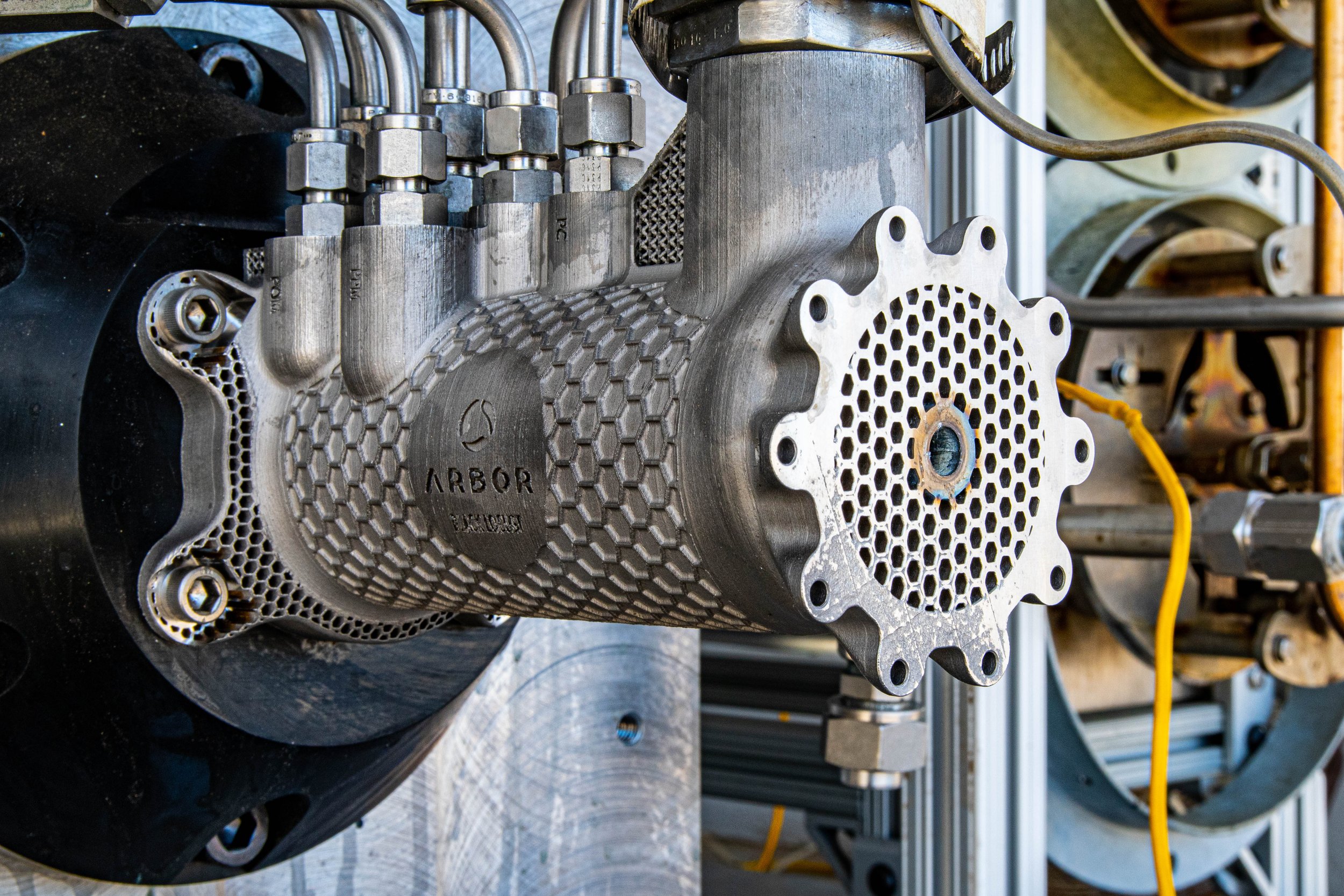

Using proven technologies and the expertise of our team—including engineers who have designed rocket engines for SpaceX and advanced gas turbines for GE—we’ve created a solution that eliminates the emissions, large footprint, and complexity of traditional power plants. Our system is smokestack-free, requires half the construction time, and efficiently runs on low-grade waste that would otherwise go unused.

Arbor’s approach is a practical, affordable way to address climate change and meet humanity’s energy needs. It’s a system built to tackle today’s challenges while ensuring a thriving planet for future generations.

-

Carbon-negative power goes beyond simply generating clean electricity—it actively removes more CO₂ from the atmosphere than it emits.

Traditional fossil fuel energy sources add to climate change by releasing carbon that’s been stored underground for millions of years. When we burn these fuels, we disrupt the balance, adding carbon to the atmosphere that hasn’t been there for millennia. Most renewable energy sources are considered carbon-neutral—generating power without adding new emissions, but not actively reducing them either.

Arbor’s power, on the other hand, is carbon-negative because it actively reduces atmospheric CO₂: rather than extracting carbon from below ground and releasing it into the atmosphere, Arbor intercepts organic waste that would naturally release CO₂ and stores its carbon underground before it can complete this cycle.

This reversal is essential. Even with massive reductions in emissions, we need to actively draw down the CO₂ already in the atmosphere to effectively tackle climate change. Arbor’s carbon-negative power is designed to be part of that solution—removing emissions, not just reducing them.

-

Arbor’s system taps into nature’s own cycle to remove carbon from the atmosphere, using organic waste from agriculture, forestry, and other industries as fuel. Plants naturally absorb CO₂ through photosynthesis, capturing 400 gigatons of CO₂ from the air each year. But when plants die and decompose, or burn in wildfires, that carbon quickly returns to the atmosphere. Arbor’s process steps in to break this cycle, sequestering carbon before it’s re-released.

Here’s how it works: Arbor processes the organic waste in two stages: gasification and oxy-combustion. This approach generates electricity, but unlike conventional power plants, Arbor captures nearly all of the CO₂ produced before it can escape into the atmosphere. Once captured, the CO₂ is compressed and injected deep underground into geological formations, where it’s permanently stored and safely removed from the carbon cycle.

For every megawatt-hour (MWh) of electricity Arbor generates, about 1.7 tons of CO₂ are removed from the atmosphere, making Arbor’s electricity not just clean, but carbon-negative. By scaling this approach, Arbor offers a powerful solution to both meet today’s energy needs and reduce atmospheric CO₂, helping to bring the planet into balance.

That’s what makes Arbor’s power truly carbon-negative: we’re not just reducing emissions; we’re erasing them.

-

Arbor uses a process called Biomass Carbon Removal and Storage (BiCRS)—with a few novel advancements—to turn organic waste into clean, carbon-negative power. Here’s how it works:

Gasification of organic waste: Our process starts with organic waste from industries like forestry and farming—waste that would otherwise decompose or burn, releasing CO₂ back into the atmosphere. Arbor’s innovative gasification system converts this carbon-rich waste into a synthetic gas, ready for the next stage.

Oxy-combustion in a compact engine: Inspired by rocket technology, Arbor’s system uses pure oxygen to combust the synthetic gas in a tightly controlled reaction that produces just CO₂ and H2O. This reaction takes place within Arbor’s specially designed engine which later separates the water from the CO₂—all with zero smokestack.

Power generation with a supercritical CO₂ turbine: The intense heat generated by oxy-combustion powers a remarkably compact turbine that uses CO₂ in its “supercritical” state—where it behaves both like a gas and a liquid. This supercritical CO₂ turbine efficiently captures energy from the reaction, generating enough clean electricity to fully power the Arbor system (including oxygen generation) and supply additional baseload power for other uses.

Finally, the CO₂ produced is captured and injected deep underground into geological formations for permanent storage, safely removing it from the carbon cycle. The water produced in Arbor’s process can be repurposed for residential, agricultural, or industrial use.

Through these innovations, Arbor’s technology generates clean power and removes CO₂ from the atmosphere, bringing us closer to a planet in balance.

-

Arbor recognizes that rigorous monitoring, reporting, and verification (MRV) is essential for reliable carbon removal. We’ve partnered with Isometric to leverage their world-class Biogenic Carbon Capture and Sequestration (BCCS) Protocol to verify that our carbon removal process meets the highest standards. Our MRV framework includes detailed tracking of sustainable biomass sourcing, precise measurement of CO₂ captured from our bioenergy process, and verification of long-term geological storage, all validated through Isometric. Their comprehensive peer review process involves more than 200 climate experts to ensure the highest standards of permanence and environmental integrity.

-

At Arbor, we see the potential in what’s often overlooked. In the U.S. alone, more than 1 billion tons of organic waste are generated each year. Our system can run on a wide range of waste, transforming materials that would otherwise contribute to climate change into clean, carbon-negative power.

We work with partners across national forests, agriculture, and industry to source waste from forestry management and agricultural residues. These materials, if left unmanaged, would either decompose and release harmful greenhouse gases like methane, or contribute to problems like wildfires. Instead, we intercept this waste and put it to good use.

By using forest byproducts like overgrown brush, dead trees, and logging residues, Arbor supports healthier forests. Our approach increases the economic viability of wildfire prevention efforts and promotes long-term forest health by keeping these materials from piling up or burning in uncontrolled settings. Rather than cutting down trees for fuel, we rely on what’s already available, putting waste to work for the benefit of the environment and local communities.

In addition to forestry waste, we use agricultural residues—what gets left in the field after a crop is harvested or byproducts like grain hulls that don’t have a market. This material is often burned or left to rot in fields, releasing methane and particulates into the air. These residues offer a massive opportunity for scalable carbon removal, and by using them, we help reduce air pollution and prevent waste from contributing to climate change. Similarly, food waste and wood waste from construction, which often end up in landfills releasing methane, could be transformed into clean power through our process.

Arbor’s approach is about harnessing what’s already abundant—organic waste that would otherwise go unused—and turning it into a resource for a cleaner future. By doing so, we help solve the dual challenges of waste management and climate change.

-

Arbor operates with a “do no harm” approach, using only true waste—materials that would otherwise contribute to greenhouse gas emissions or environmental degradation. In forestry, for example, we source byproducts from wildfire mitigation efforts and hazardous fuels reduction, helping to restore and protect natural landscapes. In agriculture, we follow guidelines that ensure no more than 20-30% of crop residues are removed from the field, preserving soil health for future harvests.

By using waste streams that are both abundant and unavoidable, Arbor’s system offers a sustainable, scalable solution for renewable power and carbon removal. We’re committed to ensuring that the materials we use avoid harm to ecosystems and actively contribute to a healthier planet.

More Questions?

Let’s Chat

If you want to learn more about how Arbor’s technology can transform the way we power the planet, we’d love to hear from you.